IEEE 1017.2-2021 pdf download.IEEE Recommended Practce for Specifying Electric Submersible Pump Cable—Ethylene– Propylene Rubber Insulaton

1.1 Scope

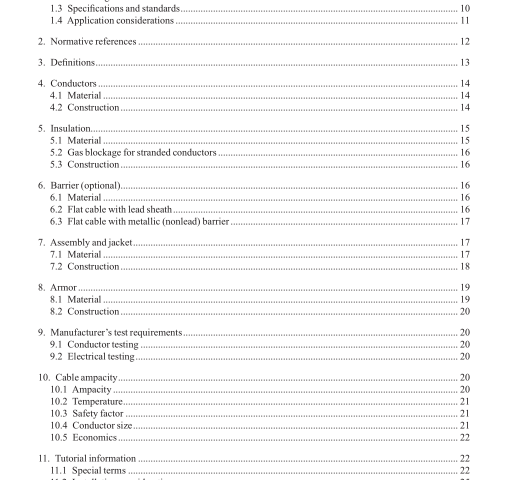

This recommended practice establishes recommendations for three-conductor round and flat oil-well cables consisting of ethylene–propylene rubber (EPR) insulated copper conductors used in supplying three-phase ac electric power to submersible pump motors. These cables may also include additional coverings consisting of wraps, metallic armor or barriers, and/or nonmetallic jackets or sheaths selected on the basis of mechanical and environmental conditions.

1.2 Word usage

The word shall indicates mandatory requirements strictly to be followed in order to conform to the standard and from which no deviation is permitted (shall equals is required to). 2,3

The word should indicates that among several possibilities one is recommended as particularly suitable,without mentioning or excluding others; or that a certain course of action is preferred but not necessarily required (should equals is recommended that).

The word may is used to indicate a course of action permissible within the limits of the standard (may equals is permitted to).

The word can is used for statements of possibility and capability, whether material, physical, or causal (can equals is able to).

1.3 Specifcations and standards

Cables meeting the requirements of the recommended practice should be rated for voltages not exceeding 8 kV (phase to phase).

Conductor operating temperatures for cables should not exceed 232 °C (450 °F). Use of cable above rated temperature can cause premature deterioration of the insulation. Low-temperature handling below –10 °C (14 °F) may cause cracking of the insulation or jacket. Cable purchased under the recommendation of this recommended practice, unless otherwise specifed herein, should meet the requirements of ASTM A90, ASTM B3, ASTM B8, ASTM B33, ASTM B189, ASTM B496, ASTM D412, ANSI/ICEA S‐96‐659/NEMA WC71, ICEA S-19–81/NEMA WC3, and ICEA S-61–402/ NEMA WC5, where applicable.

4 1.4 Application considerations While operating temperature is the main factor in selecting the type of insulation to be used, many other factors should be considered when choosing an appropriate electric submersible pump (ESP) cable design. Conductor size, insulation thickness, types of barriers or braids, jacket material, cable geometry, armor material, and thickness should all be chosen with respect to specific well and operational factors, including but not limited to the following:

— The economic impact of conductor size selection.

— Anticipated life expectancy of various cable options in specifc well conditions.

— Start-up current and maximum voltage drop to ensure motor starting capability.

— Voltage rating to optimize cable and system run life.

— The projected heat rise due to voltage imbalance.

— Available space between the tubing and the casing.

— The amount and type of gas in the well.

— Corrosiveness of the well environment.

— The effect of any corrosion inhibitors or other chemical additives on insulation properties.

— The type of annulus fuid surrounding the cable when it is set above a packer.

— The rate and frequency of decompression cycles.

— The magnitude and frequency of temperature cycles.

— Crane pick weight capacity in offshore applications.

— Inclusion of chemical injection or communication lines in the cable.

— Wellbore trajectory.

— Clamping and banding methods.

— Adjustable speed drive (ASD) harmonics that can add electrical and thermal stress to the cable.

— Considerations for thermal expansion of tubing encapsulated power cable (TEPC):

— Size and stiffness of the ESP cable may create safety concerns for standard well cable cutting tools that might not be adequate for the task under emergency (e.g., rig blow out) conditions.

— There is potential for trapped pressure inside the metal barrier when coming out of well.

— The potential for damaging foating shield currents with encapsulation, no armor and the three conductor barriers isolated.

Because many considerations are involved in making the proper cable selection, it is very important for the operator to engage the assistance of its supplier’s cable application engineers during the cable selection process. Each manufacturer has extensive experience with all the features and benefts of its particular cable offerings, and its input can be invaluable in choosing the proper cable to help maximize the value of cable investments. API 11S3 [B1] and API RP 11S5 [B3] contain information regarding the installation and application of submersible pump cable.IEEE 1017.2 pdf download.IEEE 1017.2-2021 pdf download

IEEE 1017.2-2021 pdf download

Leave a Reply