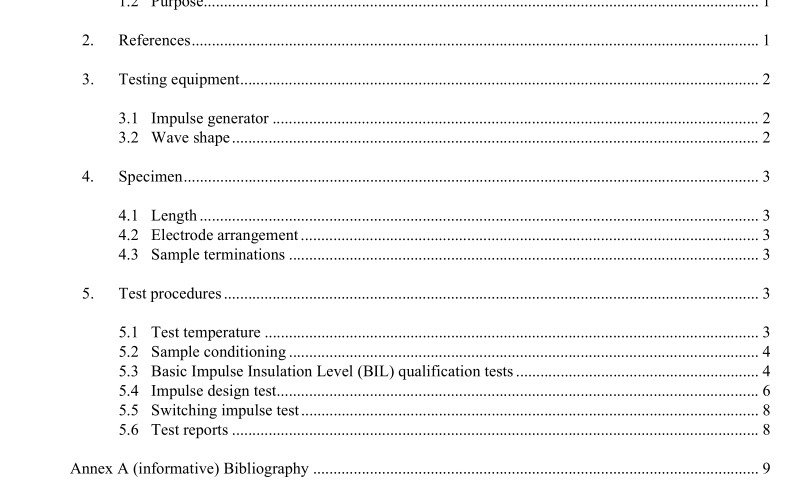

IEEE 82-2002 pdf download.IEEE Standard Test Procedure for Impulse Voltage Tests on Insulated Conductors

4. Specimen

4.1 Length A minimum cable length of 9 m between grounded ends of the test terminations, when no other accessories are involved or as required by the specific cable standard, shall be provided. When other accessories are included in the test circuit, a minimum cable test length of 4.5 m between the ends of accessories, and between the accessories and grounded end of the test terminations, shall be provided. When testing accesso- ries only, shorter cable lengths are allowed (see specific accessory standard).

4.2 Electrode arrangement

4.2.1 Inner electrode The inner electrode consists of the cable conductor, including any conductive shielding.

4.2.2 Outer electrode The outer grounded electrode depends upon the type of cable and voltage rating. a) Shielded cables. Shielded cables, including those having external metallic coverings, shall be tested in their final construction, or as agreed upon between user and manufacturer.

1) Pressurized cables and cable systems shall be tested at minimum recommended operating pres- sure, and with the design filling medium, or as agreed between user and manufacturer.

2) Other shielded cables shall be tested in air, at atmospheric pressure.

3) Other specifications may require certain extruded cables to be tested in conduit.

b) Nonshielded cables. Nonshielded cables (i.e., those having no external metallic or semiconducting coverings over the insulation) shall be tested with the active length (test sample length) in conduc- tive water that serves as the outer electrode. As an alternative, the cable may be tested in air after it has been prepared with semiconducting tape or paint and metal braid or mesh as an outer electrode.

4.3 Sample terminations If a cable or joint is being evaluated, end preparations may be test terminals, such as water terminals or resis- tive terminals. If a cable system is being evaluated, the active length shall include at least one of each type of commercial termination designated for use on the cable system. Preparation of test terminations should be conservative but adequate to ensure a test failure in the active length of the cable or the cable accessory being tested.

5. Test procedures

5.1 Test temperature The temperature of the cable conductor shall be maintained at a constant value during the test. The tempera- ture of the cable conductor shall be set at the recommended maximum continuous operating temperature (+5 °C, –0 °C) unless otherwise agreed upon. Other specifications may require individual cable system compo- nents to be tested at temperatures other than the maximum continuous operating temperature. Temperature control by conductor heating is preferred. External heating is allowed only by agreement between the par- ties. DC service application cable systems require conductor heating.

The conductor temperature may be determined either by direct measurement in a dummy cable, by direct measurements in the test sample, or by calculation if the thermal resistance of the cable insulation is agreed upon by the parties. A dummy cable is identical to the test sample and subjected to the same conditions, except that no voltage is applied. The dummy cable may be tested prior to the actual test samples.

5.2 Sample conditioning Both ends of the test sample conductor shall be connected to the impulse generator. A positive polarity impulse of 50%, then 65%, and then 80% of the intended test shall be applied to the conductor, with the outer electrode grounded. This conditioning procedure shall be repeated each time polarity is reversed, using the polarity of the impulse that will follow the conditioning. If agreed to by the parties involved, sample con- ditioning may be eliminated, which creates a more severe test condition.

5.3 Basic Impulse Insulation Level (BIL) qualification tests 5.3.1 Test level BIL levels for a voltage class are shown in Table 1 for reference purposes only. Not all cable types are avail- able in all voltage classes. Other withstand levels may be specified for some cable systems and cable acces- sories. Accessory BIL ratings may differ from these system BIL levels. A withstand level for a cable system that is different than the BIL value shown in Table 1 may be specified. In this case, the specified withstand level should be used as the BIL for the test in 5.3.IEEE 82 pdf download.IEEE 82-2002 pdf download

IEEE 82-2002 pdf download

Leave a Reply