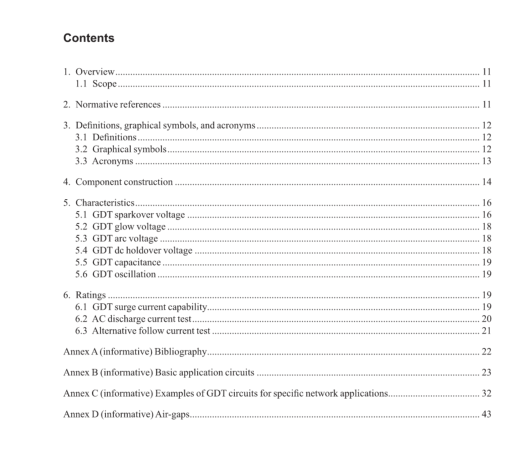

IEEE C62.42.1-2016 pdf download.IEEE Guide for the Application of Surge-Protective Components in Surge Protective Devices and Equipment Ports- -Part 1: Gas Discharge Tubes (GDTs)

4. Component construction

Gas discharge tubes consist of two or more metal electrodes separated by a small gap and held by a ceramic or glass cylinder. Figure 4 shows a two-electrode GDT.

The cylinder is flled with a noble gas mixture. When sufficient voltage is applied to the electrodes, gas spar- kover occurs into a glow discharge mode and finally a low-voltage arc condition when sufficient current is available. When a slowly rising voltage across the gap reaches a value determined primarily by the electrode spacing, gas pressure, and gas mixture, the turn-on process initiates at the sparkover (breakdown) voltage. Once sparkover occurs, various operating states are possible, depending upon the external circuitry. These states are shown in Figure 1. At currents less than the glow-to-arc transition current, a glow region exists. At low currents in the glow region, the voltage is nearly constant; at high glow currents, some arrester types may enter an abnormal glow region in which the voltage increases. Beyond this abnormal glow region the tube impedance decreases in the transition region into the low-voltage arc condition. The arc-to-glow transition current may be lower than the glow-to-arc transition current. The GDT electrical characteristic, in conjunction with the external circuitry, determines the ability of the gas tube arrester to extinguish after passage of a surge, and determines the energy dissipated in the arrester during the surge.

If the appied voltage (e.g., transient) rises rapidly, the time taken for the ionization/arc formation process may allow the transient voltage to exceed the value required for breakdown in the previous paragraph. This voltage is defined as the impulse breakdown voltage and is generally a positive function of the rate of rise of the applied voltage (ransient).

A single chamber three- electrode GDT has two cavities separated by a center ring electrode (see Figure 5). The hole in the center electrode allows gas plasma from a conducting cavity to initiate conduction in the other cavity, even though the other cavity voltage may be below the sparkover voltage. Because of their switching action and rugged construction, gas tubes exceed other voltage limiting surge protective components in current-carrying capability. Many gas tubes intended for telecommunication applications can easily carry surge currents as high as 10 kA, 8/20; further, depending on design and size of the gas tube, surge current values of> 100 kA, 8/20 can be achieved.

The construction of gas discharge tubes is such that they have very low capacitance, generally less than 2 pF.

This allows their use in many high frequency circuit applications. When GDTs (gas discharge tubes) operate, they may generate high frequency radiation, which can infuence sensitive electronics. It is therefore wise to place GDT circuits at a certain distance from the electronics.

The distance depends on the sensitivity of the electronics and how well the electronics are shielded. Another meth- od to avoid the effect is to place the GDT in a shielded enclosure.

5. Characteristics In terms of voltage limiting performance, a GDT has four key parameters; sparkover voltage, glow voltage, are voltage, and dc holdover voltage (sce Figure 6).

5.1 GDT sparkover voltage

5.1.1 DC and impulse sparkover voltgage The maximum value of limiting voltage depends on the surge voltage rate of rise. Figure 7 shows a typical relationship between the GDT de sparkover and the impulse, fast rate of voltage rise, sparkover ofa GDT. In this example, the minimum 1000 V/us sparkover voltage of 575 V occurs with a 150 V dec sparkover voltage GDT. The much lower voltage 75 V dc sparkover GDT has a 1000 V/μs sparkover voltage of 700 V- nine times higher than the dc value. Where fast rising transients occur, often the 150 V GDT will be more effective thana 75 V GDT.

Figure 7 shows absolute values of voltage. In terms of relative voltage increase, then this factor continuously decreases with increasing voltage, being;9 at 75 V, 4 at 150 V, 2.6 at 300 V and2.1 at 600 V. For example, two 150 V GDTs in series would have a 1000 V/us sparkover of 1150 V, but a single 300 V GDT would have a 1000 V/us sparkover of 775 V. Two or more series connected GDTs will always have a net 1000 V/us sparkover voltage higher than the equivalent single GDT. These numbers are just for demonstration of GDT characteris- tics and may vary for different designs.IEEE C62.42.1 pdf download.IEEE C62.42.1-2016 pdf download

IEEE C62.42.1-2016 pdf download

Leave a Reply