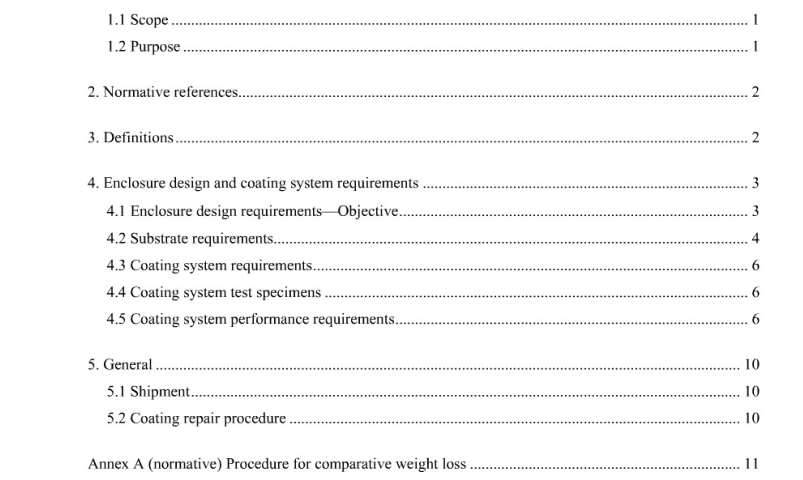

IEEE C57.12.30-2010 pdf download.IEEE Standard for Pole-Mounted Equipment-Enclosure Integrity for Coastal Environments

4.2 Substrate requirements

4.2.1 General

The substrate shall be a material that, when coated or otherwise processed, will maintain the structural integrity of the enclosure over the life of the apparatus.

4.2.2 Specification of substrate characteristics The apparatus enclosure substrate shall exhibit a general corrosion rate not to exeed 0.03 mm (0.001 in) per year and a maximum pit depth not to exceed 0.13 mm (0.005 in) over the life of the apparatus, when exposed to natural corrosive environments.

4.2.3 Substrate performance requirements Five substrate test panels and five AISI 409 stainless-steel control test panels shall be evaluated for percent weight loss after exposure to 1500 h of salt spray in accordance with ASTM B117.

The average weight loss of each set of test panels shall not exceed 2.5%. In addition, the ratio of the average percent weight loss between the substrate test panel set and the control test panel set shall not exceed5 to 1.° The AISI 409 stainless-steel control test panels shall be unwelded but fabricated and pretreated in accordance with Figure 2 (non-welded panel) using standard production practices prior to testing. For metallic substrates, the substrate test panels shall be fabricated in accordance with Figure 1 (welded panel) using standard production, fabrication, welding, and cleaning practices. For non-metallice substrates, the substrate test panels shall be fabricated in accordance with Figure 2 using standard production, fabrication, and cleaning practices.

4.3 Coating system requirements

4.3.1 General

All coated surfaces of the enclosure that may be exposed to the atmosphere shall be capable of meeting the performance tests required by this standard.

4.3.2 Specification of coating characteristics

If more than one coating system is used for different areas of the enclosure, the areas in which each is used shall be identified. The laboratory test performance data of each coating system shall be identified. The laboratory test performance data of each coating system shall be submitted for approval upon request. This data shall be resubmitted whenever there are changes in the method and/or materials, or every 2 years.

4.3.3 Coating touch-up prior to shipment

Touch-up, when required, shall be done at final inspection before any equipment is shipped. In areas where the integrity of the coating system is violated, the touch-up shall blend smoothly and meet all performance criteria of this standard.

4.3.4 Enclosure color

Unless otherwise specified, the topcoat color shall be Munsell Number 5BG 7.0/0.4 (ANSI Gray No.70).

The color variation of the coated product shall not exceed the Munsell Color Standard by more than a 0E

(Hunter) value of two. See Munsell Color Standards [B16].

4.4 Coating system test specimens

Test specimens shall consist of panels of the same material composition used in production. Test specimens shall be in accordance with Figure 3, Figure 4, Figure 5, and Figure 6 as to size and type. Quantity and typeof panels in each test are identified under the specific test. All panels shall be cleaned, coated, and curedusing the production coating system. Coated test panels shall be conditioned at room temperature andhumidity for a minimum of 7 days prior to any testing.

4.5 Coating system performance requirements

4.5.1 Exposure test

4.5.1.1 Exposure test site

A marine environment for natural accelerated testing, located on the ocean or Gulf of Mexico, with a view of the surf line that is unrestricted by buildings. Corrosion rate for an ingot of iron of AISI 1008 carbon steel shall be greater than 254 um (10 mil) per year as determined by annual evaluation. Monitoring for chloride deposition (monthly), iron ingot corrosion rate (annual), temperature, and rainfall shall be maintained and historical data provided upon request.

NOTE- Examples of test sites that meet these criteria are Battelle Memorial Institute’s Florida Materials Research Facility (Daytona Beach, Florida) and the Corrosion Technology Laboralory (Kennedy Space Center, Florida).IEEE C57.12.30 pdf download.IEEE C57.12.30-2010 pdf download

IEEE C57.12.30-2010 pdf download

Leave a Reply