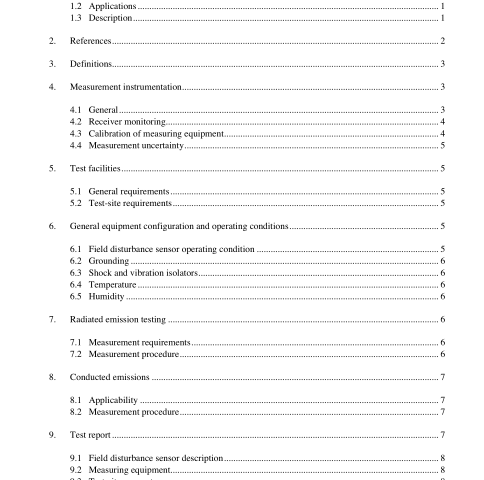

IEEE 475-2000 pdf download.IEEE Standard Measurement Procedure for Field Disturbance Sensors 300 MHz to 40 GHz

3. Definitions

For definitions of terms used, see ANSI C63.14-1992 and The IEEE Standard Dictionary of Electrical and Electronic Terms [B5].

4. Measurement instrumentation

4.1 General Use of proper measurement instrumentation is critical to obtaining accurate, reproducible results.

4.1.1 Measuring instruments The measurement instrument chosen for each required measurement shall satisfy the minimum specifica- tions herein.

4.1.1.1 Power flux density The instrument used to measure power flux density shall comply with IEEE Std C95.3-1991.

4.1.1.2 Frequency The fundamental transmitter frequency ( f o ) shall be measured. A spectrum analyzer, receiver, microwave fre- quency counter, or commercial frequency meter may be used, provided the frequency of the measurement instrument is accurate enough to ensure that the device is operating within the specified frequency band.

4.1.1.3 Field strength The field strength shall be measured using a calibrated receiver or spectrum analyzer with an expanded amplitude uncertainty of ±2 dB and a minimum dynamic range of 50 dB coupled to a suitable antenna (see 4.1.2).

4.1.1.3.1 Detector function The detector function shall conform to the requirements of ANSI C63.2-1987. Unless otherwise specified by the procuring authority or regulatory authority, the detector function for frequencies at or below 1 GHz shall be quasi-peak, and for frequencies above 1 GHz, shall be average. When the field disturbance sensor employs pulse modulation techniques, measurements shall also be made using a peak detector.

4.1.1.3.2 Bandwidth At frequencies of 1 GHz and below, the 6 dB measurement bandwidth shall be 120 kHz. Above 1 GHz the 6 dB bandwidth shall be 1 MHz ±20%. When using a peak detector, the 6 dB bandwidth shall be not less than 1/ t where t equals the minimum pulse width being measured.

4.1.2 Antennas Calibrated linearly polarized log periodic or horn antennas shall be used. Horns include double ridge guide horns, rectangular waveguide horns, pyramidal horns, optimum gain horns, and standard gain horns. Table 1 lists the maximum limit on horn antenna size for a 3 m measurement distance such that the far field criteria (2 d 2 / λ ), is satisfied, ( d is the separation distance between the antenna and the object under test, and λ is the wavelength at the indicated frequency).

4.2 Receiver monitoring

All emissions shall be monitored using instrumentation with a headset, in combination with an oscilloscope or spectrum analyzer.

4.3 Calibration of measuring equipment Instrumentation used for these measurements shall be calibrated on a periodic basis in accordance with ANSI/NCSL Z540.1-1994.

4.3.1 Antenna calibration

All antennas shall be individually calibrated at a minimum of 1 y intervals to show traceability to a standards developing organization. Calibration shall be performed at a measurement distance of 3 m and a height of 1 m above the ground using one of the methods specified in IEEE Std 149-1979 or ANSI C63.4-1992. An antenna calibrated at a distance 2 d 2 / λ may be used to make the measurements at any distance greater than 2 d 2 / λ .

4.3.2 Cable and waveguide calibration

Cables and waveguides used for connection of the antenna to the measuring instrument shall be calibrated for loss using the procedures of IEEE Std 474-1973. Checks shall be made frequently for deterioration caused by exposure to the environment and physical wear.

4.3.3 Measuring instrument calibration

The measuring instruments used to measure field strength, frequency, and power flux density shall be calibrated periodically to verify conformance to the manufacturer’s specifications and requirements of this standard.

4.4 Measurement uncertainty

Measurement uncertainty reflects the quality and accuracy of a measured result as compared to the true value. Such statements are generally required when reporting results of measurements so that it is clear to the user of these measurement results that the results may differ due to the measurement uncertainty of the investigator’s instrumentation, measurement techniques, and even in the standard used to set up the test itself. Most uncertainties are calculated using the tolerances of the instrumentation used in the measurement, the measurement setup variability, and the technique of the tester in performing the test.

Typically, the overall uncertainty is calculated, in part, by identifying uncertainties in the instrumentation chain used. Each will need to be evaluated as to their individual uncertainties. Measurement uncertainty shall be calculated in accordance with the procedures of ANSI/NCSL Z540.2-1997 and reported with the measurement results.IEEE 475 pdf download.IEEE 475-2000 pdf download

IEEE 475-2000 pdf download

Leave a Reply