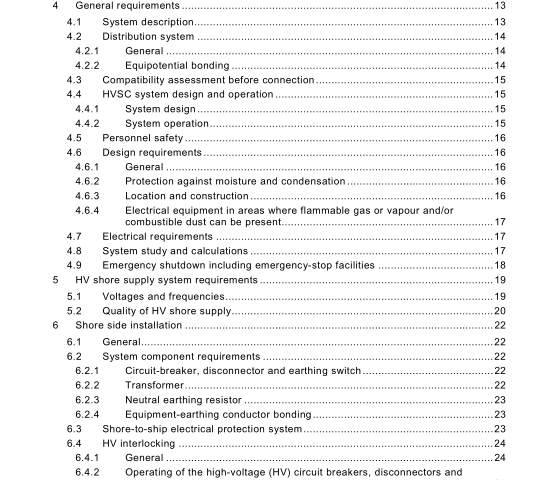

IEC IEEE 80005-1-2019 pdf download.Utility connections in port – Part 1: High voltage shore connection (HVSC) systems – General requirements

4.2 Distribution system

4.2.1 General Typical distribution systems used on shore are given in IEC 61 936-1 .

Typical ship distribution systems are given in IEC 60092-503.

NOTE IEEE Std 45.1 ™ and IEEE Std 45.3™ provide additional information on typical ship distribution systems.

4.2.2 Equipotential bonding An equipotential bonding between the ship’s hull and shore earthing system shall be provided, (see 6.2.4).

In order to assure the integrity of the bonding in the shore connection, two alternative procedures are allowed:

a) Continuous monitoring of the bonding. Verification of the equipotential bonding shall be a part of the safety circuit. Loss of equipotential bonding shall result in the shutdown of the HVSC system, and the ship shall go into ship power restoration mode (see 8.6).

b) Periodic testing and maintenance of the bonding connections. Where continuous monitoring of the quipotential bonding is not in place, periodic testing and maintenance of the bonding connections shall be performed and documented (see Clause 1 1 ).

NOTE The terms earth(ing) and ground(ing) are used interchangeably throughout this document and have the same meaning (see IEC 60050-1 95:1 998,1 95-01 -08). Equipotential bonding as protection against lectric shock is described in IEC 61 1 40.

4.3 Compatibility assessment before connection

Compatibility assessment shall be performed to verify the possibility to connect the ship to shore HV supply. Compatibility assessment shall be performed prior to the first arrival at a terminal.

Assessment of compatibility shall be performed to determine the following:

a) compliance with the requirements of this document and any deviations from the recommendations;

b) minimum and maximum prospective short-circuit current (see 4.7 and 4.8);

c) nominal ratings of the shore supply, ship to shore connection and ship connection (see 5.1 );

d) any de-rating for cable coiling or other factors (see 7.2.1 );

e) acceptable voltage variations at ship switchboards between no-load and nominal rating (see 5.2);

f) steady-state and transient ship load demands when connected to a HV shore supply, HV shore supply response to step changes in load (see 5.2);

g) system study and calculations (see 4.8);

h) verification of ship equipment impulse withstand voltage;

i) compatibility of shore and ship side control voltages, where applicable;

j) compatibility of communication method and means;

k) distribution system compatibility assessment (shore power transformer neutral earthing);

l) functioning of ship earth fault protection, monitoring and alarms when connected to an HVSC supply (see 8.2.2);

m) sufficient cable length;

n) compatibility of safety circuits;

o) total harmonic distortion (THD) (see 5.2);

p) consideration of hazardous areas, where applicable (see 4.6.4);

q) when a HV supply system is connected, consideration shall be given to provide means to reduce current in-rush and/or inhibit the starting of large loads that would result in failure,overloading or activation of automatic load reduction measures;

r) consideration of electrochemical corrosion due to equipotential bonding;

s) utility interconnection requirements for load transfer parallel connection;

t) equipotential bond monitoring (see 4.2.2).

4.4 HVSC system design and operation

4.4.1 System design

The design and construction shall be integrated and coordinated among the parties responsible for shore and ship HVSC systems.

System integration of shore and ship HVSC systems shall be managed by a single designated party and shall be performed in accordance with a defined procedure identifying the roles,responsibilities and requirements of all parties involved.

4.4.2 System operation

During the operation of HVSC systems, the person in charge [PIC(s)] shall be identified at the shore facility and onboard the ship for the purposes of communication.

The PIC(s) shall be provided with sufficient information, instructions, tools and other resources for safety and efficiency of these activities.

An independent means of voice communication should be provided between the ship and the facility’s PIC (e.g. two-way radios).

4.5 Personnel safety

Construction of the HV equipment and operating safety procedures shall ensure the safety of personnel during the establishment of the connection of the ship’s supply, during all normal operations, in the event of a failure, during disconnection and when not in use.

NOTE The use of the term “safe” is not intended to suggest or guarantee that absolute safety can be achieved in any situation and/or by compliance with the recommended practices set forth herein.

The use of terms such as “safe”, “intrinsically safe”, “electrically safe work practices”, “safe work condition”, “safe work environment”, “safe design”, “safe distance”, “safe work method”, “safe work area”, and “safe use” describe practices, conditions, etc. in which safety risks are minimized but not eliminated absolutely, such that safety is not guaranteed.

4.6 Design requirements

4.6.1 General Protection and safety systems shall be designed based on the fail-safe principle, hard wired. Suitable warning notices shall be provided at locations along connection-equipment routes, including connection locations.IEC IEEE 80005-1 pdf download.IEC IEEE 80005-1-2019 pdf download

IEC IEEE 80005-1-2019 pdf download

Leave a Reply