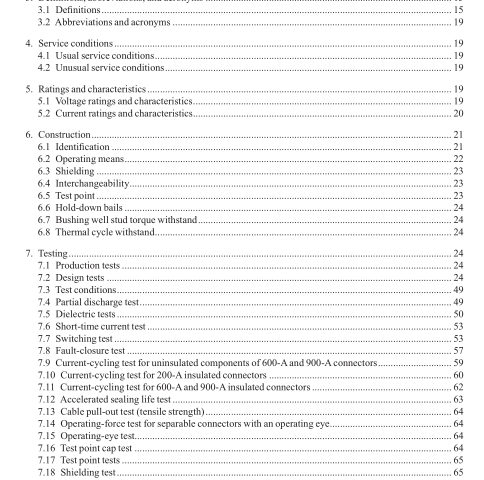

IEEE 386-2016 pdf download.IEEE Standard for Separable Insulated Connector Systems for Power Distribution Systems Rated 2.5 kV through 35 kV

6.3 Shielding

Connectors shall have an electrically conductive shield and, where required, shall have provision for connecting an external ground to the shield. Except for non-elastomeric components, connectors shall meet the requirements of IEEE Std 592.

6.4 Interchangeability Interchangeability implies that parts from one manufacturer when mated with parts of another manufacturer meet all the applicable requirements of this standard. Interchangeability is demonstrated when:

a) A part meets the design tests and the dimensional requirements, as ilustrated in this standard, where applicable.

b) In addition, 200-A and 600-A loadbreak connectors shall demonstrate conformance with switching (7.7) and fault close (7.8) test requirements when tested with intermixed bushings and elbows of dif- ferent manufacturers.

6.4.1 Interface dimensions

The dimensions of operating and bushing well interfaces shall be in accordance with Figure 2, Figure 3, Fig- ure 4, Figure 5, Figure 6, Figure 7, Figure 8, Figure 9, Figure 10, Figure 13, Figure 14, Figure 15, Figure 16 Figure 17, and Figure 18. 6.4.2 Stacking dimensions Upon request, each manufacturer shall supply the dimensions in Figure 21, Figure 22, and Figure 23. The stacking,“S,” dimensions enable users to determine the dimensional effect of stacking components.

The mounting,“M.,” dimensions enable users to determine the depth that a bushing well or integral bushing proj- ects into the apparatus on which it is mounted. A mounting,“M,” dimension is also provided for multi-way junction brackets.

6.5 Test point

Test points are optional and may be specified on any connector.

6.5.1 Capacitance Test points shall be capacitively coupled to the conductor system and shield of the connector.

The capacitance between the test point and the conductor system shall be at least 1.0 pF. The ratio of the ca- pacitance between test point and shield to the eapacitance between test point and conductor system shall not exceed 12.0.

These values shall be verified by tests when conducted in accordance with7.17.I.

6.5.2 Cap removal force

The force required to remove the test-point cap shall be within the range of 36 N to 218 N (8 Ibfto 491bf). The cap openating eye shall be capable of withstanding a static operating force of 445 N (100 Ibf) over the environmental temperature range of -20 °C to +65 °C (see 7.16.1).

6.6 Holddown bails Dimensions and materials are not specified in this standard. 6.7 Bushing well stud torque withstand The 3/8*-16 threaded stud in the bushing well shall withstand a minimum torque of23 N.m(17 ftIbf) without stipping or fracturing(see 7.19).

6.8 Thermal cycle withstand Nonelastomerie conmector components shall withstand tempernture cyeling from -40 °C to +130 °C without cracking, breaking. or imparing the ability to meet the other requirements of this standard when tested accord- ing to the procedure in 7.20.

7. Testing

7.1 Production tests

The fllowing production tests shall be performed by the manufacturer on all cnnector components except grounding devices:

a) Prtial discharge test (see 7.4) b) AC withstand or fllwave impulse withstand voltage (see 7.5.1 and 7.5.3)

d) Test-point voltage test if applicable (see 7.17.2)

Connectors shall be properly assembled with actual or simulated components that duplicate the fit and voltage stress distribution of the actual components. Bushing wells may be sample tested in accordance with ANSUASQ Z1.4 2003 (R2013) zero-bused 1.0% AQL sampling plan

7.2 Design tests The design tests listed in Table 8 shall be performed by the manufacturer to demonstrate compliance of the design with this standard. Design tests shall be performed using actual connector system components assem- bled according to the manufacturer’s instructions and using those materials supplied in the manufacturer’s packaging.IEEE 386 pdf download.IEEE 386-2016 pdf download

IEEE 386-2016 pdf download

Leave a Reply