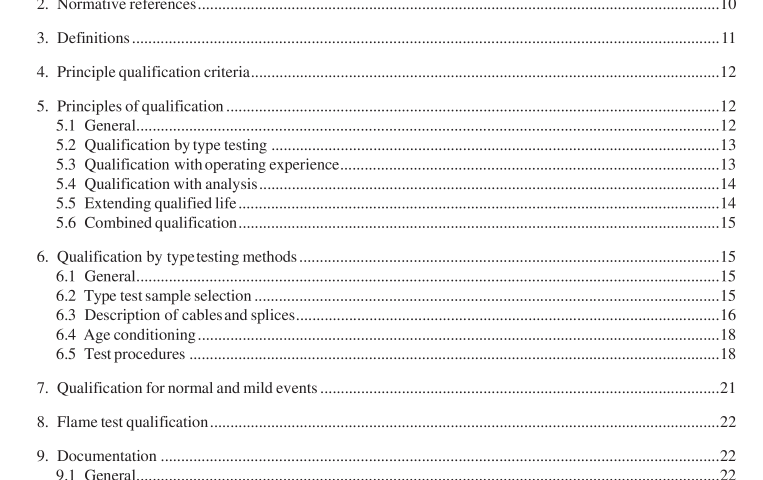

IEEE 383-2015 pdf download.IEEE Standard for Qualifying Electric Cables and Splices for Nuclear Facilities

3. Definitions

For the purposes of this document standard, the following terms and definitions apply. The IEEE Standards Dictionary Online should be consulted for terms not defined in this clause.

factory rework: The addition or reapplication, during factory production, of insulation, extruded semiconducting layers, or jacket material on a portion of a manufactured length of conductor or cable. factory splices: The inclusion by the manufacturer of a joint and requisite re-insulation of the immediate splice zone to enable a cable of the required length to be manufactured and delivered.

nuclear facilities: Structures, buildings, and systems provided that utilize, process or store fissionable material (i.e., nuclear power plant, reprocessing plant, storage facility).

representative cable: A cable or group of cables used during qualification testing to represent a number of cable styles.

The representative cables shall contain the following characteristics of the cable styles:

a) manufactured by a specific manufacturer using the same processes and controls;

b) contains the same materials, including insulation, jackets, fillers, binder tape, shields, and factory splices (if appropriate);

c) the same voltage class or higher service rating;

d) the same or higher volts per mil operating electrical stress level; and

e) construction or configuration features (e.g., number or type of conductors) that conservatively represent the features of the cable styles being qualified.

representative splice: A splice or group of splices used during qualification testing to represent a number or range of splice styles. The representative splices shall contain the following characteristics of the splice styles: a) materials manufactured by a specific manufacturer using the same processes and controls, b) the same materials, c) the same voltage class, or higher service rating d) the same or higher volts per mil operating electrical stress level, and e) construction or configuration features (e.g., number of conductor break-outs, V-type or inline type) that conservatively represent the features of the splice styles being qualified.

wire: A single insulated conductor.

4. Principle qualification criteria

It is required that Class IE cable and field splices meet or exceed specified performance requirements throughout their installed life.

This is accomplished, in part, by ensuring that cables are manufactured in accordance with applicable industry standards (as defined in Clause 7) and that cables and field splices are subjected to quality assurance programs that include, but are not limited to, design, qualification, and production quality control.

It is the role of qualification to ensure that Class IE cable and field splices can be demonstrated to perform as specified and that no failure mechanism exists that could lead to common-cause failures under postulated service conditions.

It is the Degradation with time (aging), followed by exposure to the environmental extremes of temperature, pressure, humidity, radiation, mechanical stress, or chemical spray or a combination of these resulting from design-basis events (DBEs, which) present a potential for common-cause failures of Class IE cable and field splices. For these reasons, it is necessary to establish a qualified life for cables and field splices required to function during and following DBEs, which subject the cables and field splices to DBE environments that exceed their normal and abnormal levels. This shall be accomplished using the qualification methods described in the following clauses sections of this standard, including type testing, operating experience, analysis as a supplement to type testing and operating experience, ongoing qualification, or any combination thereof.

For whichever qualification method is chosen, upon conclusion of the qualification program, documentation is required that demonstrates cable and field splice adequacy to perform Class IE functions. The documentation shall be in an auditable form that allows verification by competent personnel, other than the qualifier, and shall contain the following:

— The cable or field splice’s specification or qualification plan

— The documents that demonstrate compliance with the qualification plan

— Inspection and maintenance requirements

— Summaries and conclusions.IEEE 383 pdf download.IEEE 383-2015 pdf download

IEEE 383-2015 pdf download

Leave a Reply