IEEE 420-2001 pdf download.IEEE Standard for the Design and Qualification of Class 1E Control Boards, Panels, and Racks Used in Nuclear Power Generating Stations

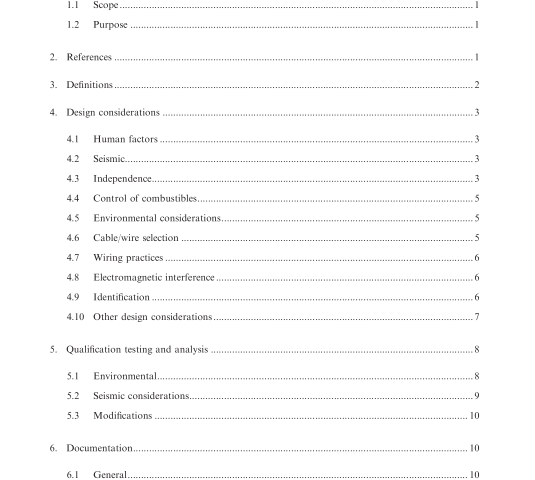

4. Design considerations

4.1 Human factors

The design/layout of the Class 1E control board, panel, or rack shall incorporate human factors engineering principles (see IEEE Std 1023-1988 for further guidance).

4.2 Seismic

4.2.1 General

The structure for a Class 1E control board, panel, or rack shall enable the equipment contained therein to meet its essential performance requirements during and after the postulated design basis earthquake. The Class 1E control board, panel, or rack should be designed to minimize the acceleration levels to which the equipment must be qualied. In minimizing the acceleration levels, consideration shall be given to existing qualication levels of equipment. For further guidance see ANSI/IEEE Std 344-1987.

In designing the control board, panel, or rack, consideration shall be given to the location of the devices mounted upon it or within it. The designer’s responsibility is to optimize the eectiveness of the control board, panel, or rack as a suitable structure for mounted devices. The designer should also consider location and availability of component mounting surface areas for future modications and additions.

4.2.2 Other considerations

Provisions shall be included for mounting the control board, panel, or rack to its supporting structure.

The interaction of the plant cable, raceway, and tubing systems entering and/or attached to the control board, panel, or rack shall be considered.

Plug-in equipment, slide-mounted equipment, or devices with access doors shall be provided with mechanical restraints, if needed, to maintain positional integrity.

All non-Class 1E devices within or attached to Class 1E control boards, panels, or racks shall be mounted to preclude degradation of Class 1E equipment or circuits, or both, beyond an acceptable level, as a result of a seismic event. Where relative motion exists between equipment mounted on or in a control board structure, the maximum range of such motion shall be considered in the physical arrangement and design parameters for wiring and adjacent equipment.

Wiring to equipment and termination devices should have sucient slack or be installed in such a way that relative motion within the control board, panel, or rack does not cause failure.

4.3 Independence

The general requirements for achieving electrical independence of redundant Class 1E equipment and circuits are contained in ANSI/IEEE Std 384-1992.

4.3.1 Design considerations Specic guidelines that shall be used in the application of the physical separation criteria in ANSI/ IEEE Std 384-1992 to the design of control boards, panels, and racks are as follows:

a) The preferred method for achieving physical separation is to locate redundant Class 1E equipment and circuits on separate control boards, panels, and racks that are physically separated from each other in accordance with the general independence criteria of ANSI/IEEE Std 384-1992. This method is suggested for panels or racks not requiring operator interface, such as termination cabinets.

b) Where operational and human factors considerations dictate, redundant Class 1E equipment or a mixture of Class 1E and non-Class 1E equipment may be located on the same panel, provided that specied separation criteria, established for this purpose in ANSI/IEEE Std 384-1992, are met within the control board.

4.3.2 Circuitry considerations When redundant Class 1E circuits or a mixture of Class 1E, associated, and non-Class 1E circuits are to be located within the same control board, panel, or rack, the specic separation criteria for control switchboards in ANSI/IEEE Std 384-1992 shall be met. To facilitate meeting the physical separation criteria, the following factors shall be considered in the design and construction of Class 1E control boards, panels, and racks:

a) Termination areas and cable entrance areas provided for external (eld) cables shall be designed and located so that the minimum physical separation requirements of ANSI/IEEE Std 384-1992 for external cables can be maintained at the point of cable entrance into the control board, panel, or rack. Separate cable entrances, wire ducts, and termination areas are a preferred means for meeting these requirements.

b) Equipment and components installed in Class 1E control boards, panels, and racks shall be located to meet the physical separation requirements for Class 1E, associated, and non-Class 1E circuits.

c) Internal wiring shall be routed and supported such that the designed physical separation is maintained throughout the life of the Class 1E control board, panel, or rack.

4.3.3 Acceptable separation distances and barriers

The specic physical separation distances are provided in ANSI/IEEE Std 384-1992. If the minimum allowable separation distance cannot be maintained (and analysis is not used), ANSI/IEEE Std 384-1992 allows the installation of barriers between the equipment and wiring that requires separation. Examples of acceptable barriers for use within Class 1E control boards, panels, and racks are as follows:

a) Metallic conduits that are not in contact with each other

b) A single sheet of re-retardant material with cable touching only one side of the barrier.IEEE 420 pdf download.IEEE 420-2001 pdf download

IEEE 420-2001 pdf download

Leave a Reply