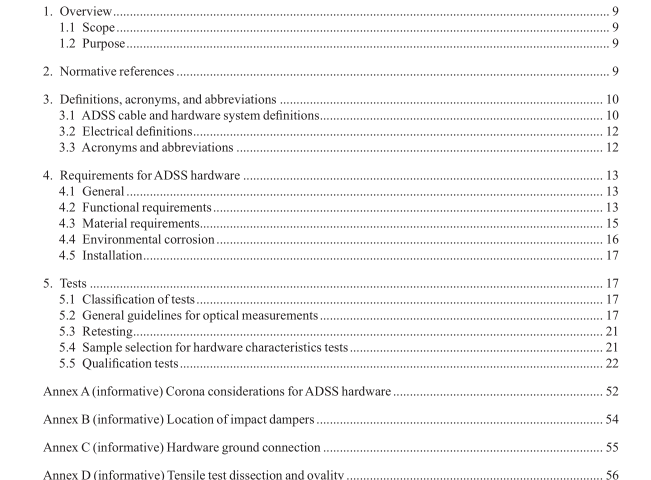

IEEE 1591.2-2017 pdf download.IEEE Standard for Testing and Performance of Hardware for All-Dielectric Self-Supporting (ADSS) Fiber Optic Cable

ISO 1461, Hot dip galvanized coatings on fabricated iron and steel articles- Specifications and test methods.

ISO 4892, Plastics- -Methods of exposure to laboratory light sources.

ISO 9227, Corrosion tests in artificial atmospheres- Salt spray tests.

3. Definitions, acronyms, and abbreviations

For the purposes of this document, the fllowing terms and definitions apply. The IEEE Standards Dictionary Online should be consulted for terms not defined in this clause.”

3.1 ADSS cable and hardware system definitions breaking strength: The calculated maximum tensile load that the cable is estimated to reach upon mechanical failure. Mechanical failure is primarily associated with the cable strength member however other cable components may contribute to the overall strength. The maximum rated cable load is typically less than 60% of the breaking strength.

Syn: breaking tension. every day tension (EDT): The final tension with no ice and no wind at the average annual mean temperature throughout the year. This temperature is assumed as 16 °C (60 °F). This number is often used in specifying motion control devices such as vibration dampers. hardware: Attachments or ftings that are in direct contact with the cable.

maximum hardware safety tension (MHST): This is the maximum hardware tension rating for dead-end hardware to hold all dielectric self-supporting cable that can exceed the cable maximum rated cable load (MRCL) rating.

Maximum hardware safety tension is greater than the maximum loaded tension (MLT) or MRCL and may approach the cable estimated breaking strength. If the hardware tension rating is less than or equal to the cable MRCL then the MLT terminology is used.

maximum installation tension (MIT): This is the initial tension at which the cable is pulled during the sagging portion of the installation process. This tension is used to achieve the appropriate installation sag defined by the manufacturer relative to conductors, other cables, and the ground.

Sym: sagging tension. NOTE- -This is the same as the everyday tension when specified at 16 °C (60 °F).

maximum loaded tension (MLT): The system tension that represents the tension above maximum installation tension (MIT) caused by environmental load conditions such as wind and ice. This tension shall not exceed the cable MRCL or the maximum tension allowed by the hardware (whichever is less). The load is greater than MIT but less than or equal to maximum rated cable load (MRCL).

It is also referred to as maximum operating tension or short-term load. It may also be referred to as the National Electric Safety Code* (NESC*) (Accredited Standards Committee C2-2012 [B1]) loaded tension, which corresponds with local regions across the United States that are referenced in the NESC.

NOTE- For example, the MLT may be used in a case where the MRCL is higher than the expected loading on the cable (ic., a stronger cable used than needed) and lower strength hardware is suitable.

maximum rated cable load (MRCL): This is the maximum tensile load the cable is designed to withstand during its lifetime without reducing the performance of the optical fibers. This tension rating is determined by the cable manufacturer and is sometimes referred to as maximum rated design tension by the IEEE or the maximum allowed tension by the IEC. MRCL may be expressed in terms of tension or as a percentage of breaking strength. MRCL is typically the load the cable is designed to withstand when the cable is installed in its maximum specifed span length while experiencing the maximum specified weather load. The weather load or environmental load factors in local wind and ice load.

NOTE- See Figure 1.IEEE 1591.2 pdf download.IEEE 1591.2-2017 pdf download

IEEE 1591.2-2017 pdf download

Leave a Reply