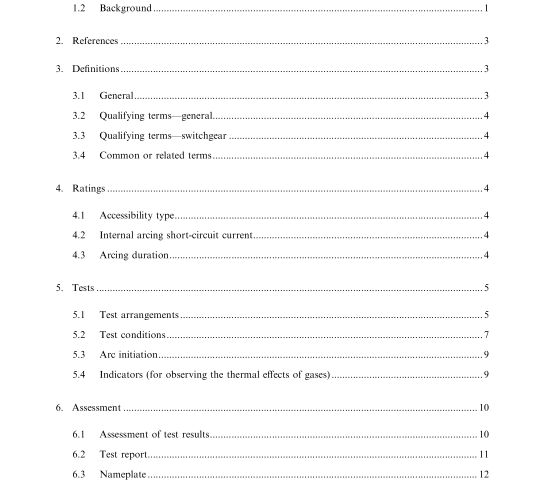

IEEE C37.20.7-2001 pdf download.IEEE Guide for Testing Medium-Voltage Metal-Enclosed Switchgear for Internal Arcing Faults

3.1.7 solid insulation: An applied insulation that is

1) homogeneous and essentially free of voids,

2) conformal to the shape of the bus, and

3) bonded to the bus in such a way that removal requires destroying the insulation. Typical examples of such insulations are epoxies or polymers applied by fluidized bed and liquid dip processes. Specifically excluded from this definition are tape, shrink tubing, and all types of boots and slip-on insulation.

3.2 Qualifying terms—general Qualifying terms are defined in IEEE 100 [B2] and the user is referred to the definitions given therein.

3.3 Qualifying terms—switchgear Qualifying terms are defined in IEEE Std C37.100-1992 and the user is referred to the definitions given therein.

3.4 Common or related terms Common or related terms are defined in IEEE Std C37.100-1992 and the user is referred to the definitions given therein.

4. Ratings

An IEEE guide cannot mandate or define equipment ratings. This guide is intended to establish a level of performance for the equipment under specific conditions. While these conditions are not an equipment rating, they are the basis of the equipment evaluation described in this guide and are listed in Clause 4 for convenience.

4.1 Accessibility type A distinction is made between two levels of accessibility to switchgear assemblies. These levels correspond directly to the indicator placement given in 5.4.2. —Type 1. Switchgear with arc-resistant designs or features at the freely accessible front of the equipment only.

—Type 2. Switchgear with arcresistant designs or features at the freely accessible exterior (front, back, and sides) of the equipment only.

4.2 Internal arcing short-circuit current The internal arcing short-circuit current is the current level to be used as the prospective current value for testing. The preferred value of the internal arcing short-circuit current is the rated short-time current of the equipment.

4.3 Arcing duration The arcing duration is the period oftime the equipment can experience the effects ofan internal arcing fault and meet the requirements specified by this guide in Clause 6. The preferred arcing duration for this test is 0.5 s at the rated power frequency of the equipment.

5. Tests

5.1 Test arrangements

5.1.1 Considerations for all equipment In the choice of test specimen configuration, the following points should be considered:

a) The test should be carried out on a compartment(s) not previously subjected to internal arcing.

b) The mounting arrangements of the test specimen should be as prescribed by the manufacturer.

c) The configuration of each vertical section should be as follows:

1) The vertical section(s) should be fully equipped. Mockups ofinternal components may be substituted, provided that they have the same volume and are of similar material as the original items.

2) The compartments within the vertical section should be representative of the minimum volume utilized for the maximum size component and the maximum unbraced wall surface utilized by the design. The sample should contain the maximum number of openings designed for equipment ventilation and the minimum number of openings designed for arc fault pressure relief.

3) All ventilation openings utilized for equipment cooling and designed to close during an overpressure event must be open and functional prior to starting the test.

4) If the equipment is intended for use with control devices, such as relays and meters, mounted on exposed doors or covers, a representative sample of these devices should be present on the test specimen. When this is not practical, the compartment directly behind the mounting point should be evaluated to verify that any abnormal pressure developed during the test will not cause the mounted devices to be displaced or allow exposure to the arc. Indicators should be placed inside this compartment to verify that the effects of the fault do not enter into the compartment.

5) Any openings created in the equipment as a result of manufacturing, assembly, or modification, which have an intentional covering, plug, or similar device, may have that device installed. Openings that do not have intentional coverings cannot be blocked in any way for this test.

d) The test specimen should be grounded at the normal ground point(s) or to the test supply neutral through an adequate conductor.

e) The arc should be initiated in a way that is representative of faults that could occur under service conditions. See 7.1 for typical locations for fault initiation.

f) When the equipment is to be installed indoors, the test arrangement should simulate room conditions in a manner that enables the manufacturer to provide application guidelines that consider the following:

1) Distance to adjacent walls

2) Ceiling height

3) Any obstruction located near the equipment that could deflect hot gas into an area defined by the accessibility type

4) Any openings beneath the equipment (cable vaults) that could allow hot gas to escape into an area defined by the accessibility type If the design incorporates an exhaust system that vents pressure directly out of the room, no room simulation is necessary.

The test sample exhaust system must be representative of the longest length utilized by the design.IEEE C37.20.7 pdf download.IEEE C37.20.7-2001 pdf download

IEEE C37.20.7-2001 pdf download

Leave a Reply