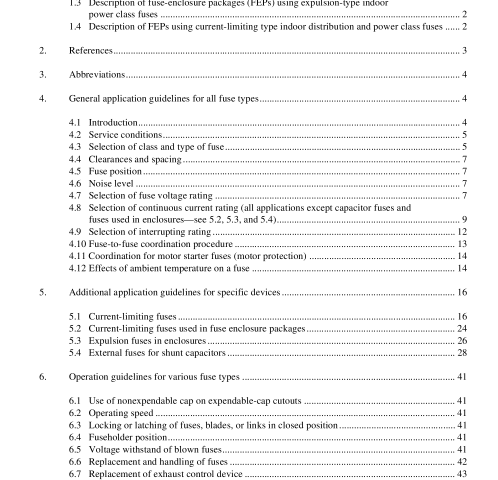

IEEE C37.48-2005 pdf download. IEEE Guide for the Application, Operation, and Maintenance of High-Voltage Fuses, Distribution Enclosed Single-Pole Air Switches, Fuse Disconnecting Switches, and Accessories

4. General application guidelines for all fuse types

4.1 Introduction

The application, operation, and maintenance of equipment covered by this guide is the responsibility of the user, who is expected to take into account system-specific requirements. As an aid in obtaining satisfactory performance of equipment, this guide provides information on some of the more important features of the above functions for normal conditions of service; unusual conditions may require special measures. Although fuses are single-phase devices, they can be applied with single- or three-phase equipment or lines, or a combination of these. However, characteristics of the power system should be considered when select- ing all fuses.

A fuse, when applied in an electric circuit within the limits of its ratings, protects the circuit. Its primary function is to isolate faulted equipment from the system. When applied with other equipment in a coordi- nated overcurrent protection scheme, it may also limit service interruptions to only a predetermined section of a power system.

In many applications, it is possible that the equipment connected to the system can be protected from excessive damage. In this latter application, the primary function is to remove the faulted equipment from the system, and the secondary function is to minimize, or in some cases prevent, damage to the connected equipment as much as possible, considering the varying fault or overload circumstances that can occur. Fuse performance depends upon the integrity, including quality assurance and quality control processes, with which the fuse was manufactured, the correctness of its application, and the attention it receives after it is installed. If not properly applied and maintained, it might not perform properly when required, which might result in considerable damage to costly equipment or extensive interruptions in service.

It cannot be stressed too strongly that prescribed safety rules and manufacturers’ recommendations and instructions should be adhered to at all times when operating or maintaining these devices near energized equipment or conductors. This is especially true for devices where air-insulated blades, insulating barriers or liners, or fuses are removed or replaced while mating contacts are energized. (In some cases, NFPA 70E, 2004 Edition may be applicable.)

4.2 Service conditions

4.2.1 Usual

Usual service conditions conforming to this guide are defined in IEEE Std C37.40-2003. These conditions specify limits in altitude and ambient temperature.

4.2.2 Unusual Unusual service conditions are defined in IEEE Std C37.40-2003, which gives examples of such conditions. Equipment covered by IEEE Std C37.40 that depends on air at atmospheric pressure for its insulating and cooling medium will have a higher temperature rise and a lower dielectric withstand when operated at altitudes higher than 1000 m.

Historically, equipment covered by IEEE Std C37.40 has used correction factors for dielectric strength and rated continuous current when applied at altitudes above 1000 m. In addition, equipment designed for standard temperature use could be used at its normal rated continuous current without exceeding ultimate standard temperature limits if the ambient temperature did not exceed the maximum ambient temperature assigned to the device in accordance with IEEE Std C37.40-2003, multiplied by an appropriate factor. Altitude correction factors are being studied by the Switchgear Committee, and will be added to IEEE Std C37.40-2003 directly or by reference when they are approved. In the meantime, users should consult the manufacturer for appropriate derating when the equipment is applied above 1000 m. If, during service, the fuse will be subjected to mechanical vibratory stress that may damage the fuse ele- ment, the manufacturer should be consulted to verify that it can withstand these conditions.

4.3 Selection of class and type of fuse No generalizations can be made about selecting the class and type of fuse that should be used at a particular location. In selection of the class of fuse, factors such as power being supplied, dielectric properties of the equipment being protected, X/R ratios, fault currents available, and transient recovery voltage (TRV) sever- ity require consideration. The major classes of fuses are power class and distribution class.IEEE C37.48 pdf download.IEEE C37.48-2005 pdf download

IEEE C37.48-2005 pdf download

Leave a Reply