IEEE N42.20-2003 pdf download.American National Standard Performance Criteria for Active Personnel Radiation Monitors

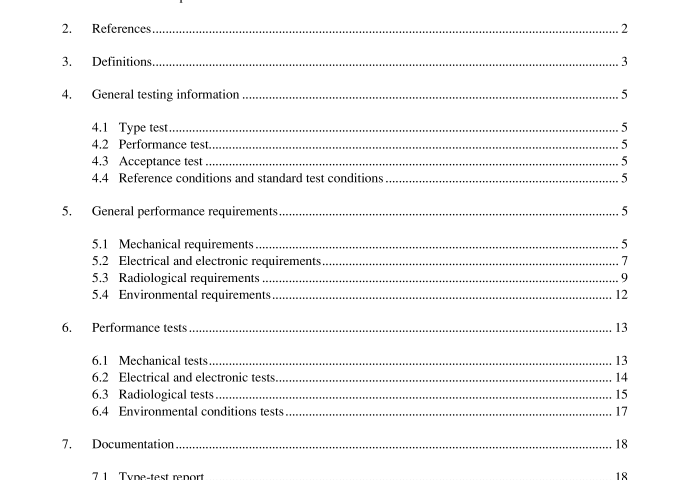

4. General testing information

The performance tests that may be used for evaluating dosimeters fall into several categories, depending upon the intended purpose. The categories are defined in 4.1, 4.2, 4.3, and 4.4, along with the applicable purposes. Not all of the tests described herein are mandatory, but such tests as are carried out shall be performed in accordance with the procedures described in this standard.

4.1 Type test

A type test is performed to determine whether a particular design of instrument will meet all of the require- ments specified in this standard. It is intended that a comprehensive type test would be performed to ensure that an instrument is acceptable for use in a particular application. If any aspect of the design of this instru- ment were to be changed, it would have to undergo another qualifying type test.

4.2 Performance test

A performance test makes use of a representative sample of instruments. The performance of this sample is tested against established criteria for performance in all relevant specifications given in this standard. Evaluation of the performance of a sample group of instruments results in either passing or failing the performance test based on the performance criteria.

4.3 Acceptance test

An acceptance test is performed to verify that a group of instruments conforms to the technical specifica- tions required for use. This test is performed subsequent to the purchase of instruments, but before they are put to use.

4.4 Reference conditions and standard test conditions

The required standard conditions for environmental quantities, such as temperature and pressure as well as those for other quantities that may influence the performance of instruments, are given in Clause 5 and Clause 6. Acceptable testing ranges for these quantities are given in Table 1 and shall be met, except where the effect of the condition or quantity itself is being tested.

NOTE—Environmental quantities, such as temperature and humidity, are referred to as influence quantities in publica- tions of IEC TC45 and its committees.

5. General performance requirements

5.1 Mechanical requirements The mechanical design specifications ensure that only instruments designed for the specific purposes out- lined in the scope of this standard are tested.

5.1.3 Case construction

The instrument case should be smooth, rigid, shock resistant, and dust and moisture resistant. Means shall be provided to attach the instrument to clothing (e.g., a strong clip, ring, or a lanyard) with attention given to the necessary orientation of the detector, alarms, and indicators.

5.1.4 Reference point marking

The instrument case shall have markings indicating the position of the effective center of detection on both the front (or back) and side of the instrument. The reference orientation with respect to the wearer shall also be marked on the instrument.

5.1.5 Resistance to contamination

The instrument case shall be constructed of materials that are easily decontaminated.

5.2 Electrical and electronic requirements

The electrical and electronic specifications of instruments or readers are given in 5.2.1, 5.2.2, 5.2.3, 5.2.4, 5.2.5, 5.2.6, and 5.2.7.

5.2.1 Scale indication The scale indication for direct reading monitors shall be digital and shall be shown in units of dose equiva- lent and/or dose equivalent rate. The display shall be clearly visible by the wearer under conditions of expected use.

5.2.2 Dose equivalent and dose equivalent rate ranges

For most applications, the dose equivalents are expected to be as follows:

Type 1 and Type 2—From 1 µSv to 1 Sv (0.1 mrem to 100 rem)

Type 3—From 10 µSv to 1 Sv (1 mrem to 100 rem)

Dose equivalent rates to be measured are expected to be as follows:

Type 1 and Type 2—From 10 µSv h –1 to 1 Sv h –1 (1 mrem h –1 to 100 rem h –1 )

Type 3—From 10 µSv h –1 to 0.1 Sv h –1 (1 mrem h –1 to 10 rem h –1 )

5.2.3 Effective range of measurement or indication

The effective range of measurement shall not be less than from the first non-zero indication in the second least significant digit up to the maximum indication on each range. As an example, for a display with a max- imum indication of 199.9, the effective range must extend from 1.0 to 199.9. Where more than one detector is used for measurement over the complete range, automatic switching shall be provided between the detectors. The tests of this standard shall be performed for all detectors. Where the instrument has range change facilities, these shall also be automatic.IEEE N42.20 pdf download.IEEE N42.20-2003 pdf download

IEEE N42.20-2003 pdf download

Leave a Reply