IEEE 112-2017 pdf download.IEEE Standard Test Procedure for Polyphase Induction Motors and Generators

3.1.4 Frequency

For general testing, the average frequency shall be within ±0.5% of the value required for the test being conducted, unless otherwise specified. Any departure from the specified frequency during the test directly affects the efficiency obtained with Efficiency Test Methods A, B, and B1. When these methods are used, the average frequency shall be within ±0.1% of the specified test value. Rapid changes in frequency cannot be tolerated during testing because such variations affect not only the machine being tested, but also the output measuring devices. Variations in frequency during a test shall not exceed 0.33% of the average frequency.

3.2 Types of tests

3.2.1 Typical Polyphase induction machines are normally given a routine test, but they may also be given additional tests. For machine tests included in a typical routine test, refer to NEMA MG 1 parts 12 and 20. A typical form for reporting routine test data is shown in Annex B. A typical form for reporting additional test data is shown in Annex C.

3.2.2 Preliminary tests The measurement of the winding resistance is commonly the first test performed. The resistance or the continuity of all windings and circuits should be measured at this time. The ambient temperature is measured using the procedure of IEEE Std 119. If the machine has embedded detectors, these may be used to confirm that the winding is at the ambient temperature.

3.2.3 Idle running tests Running tests without load are made for the determination of core loss and windage and friction losses. Some other tests such as shaft voltage (see 8.3) may also be performed under these conditions.

3.2.4 Tests with load Tests with load are made for the determination of efficiency, power factor, speed, current, and temperature rise. Some of the miscellaneous tests outlined in Clause 8 are also made with load. For all tests with load, the machine shall be properly aligned and securely fastened. For readings to be used in performance determinations, unless stated otherwise, the machine temperature rise shall be some value between 50% and 120% of the rated temperature rise. The usual procedure is to take readings at higher loads first and then follow with readings at lower loads.

3.2.5 Tests with rotor locked

It should be recognized that the testing of induction machines under locked-rotor conditions with polyphase power involves high mechanical stresses and high rates of heating. Therefore, the following is necessary:

a) The mechanical means of securing the machine and locking the rotor are of adequate strength to prevent possible injury to personnel or damage to equipment.

b) The direction of rotation is established prior to the test.

c) The machine is at approximately ambient temperature before the test is started.

The current and torque readings shall be taken as quickly as possible, and to obtain representative values, the machine temperature should not exceed rated temperature rise plus 40 °C. The readings for any point shall be taken within 5 s after test voltage is reached.

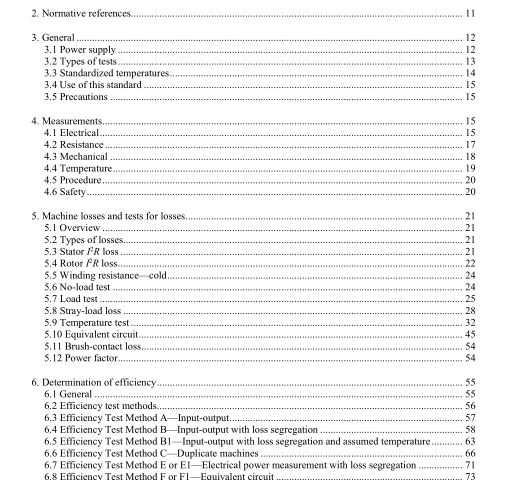

3.2.6 Choice of tests A complete list of tests covered by this standard is given in the table of contents. Alternate methods are described for making many of the tests suitable for different sizes and types of machines and different conditions. In some cases, the preferred method is indicated. Also, see 6.2.2. The schedule of factory and field tests that may be required on new equipment is normally specified by applicable standards or by contract specifications. The manufacturer’s choice of method for factory or field tests on new equipment shall govern in lieu of prior agreement or contract specification.

3.3 Standardized temperatures

3.3.1 Reference ambient temperature The reference ambient temperature shall be 25 °C. If the ambient temperature during any performance test differs from the reference ambient, the performance determinations shall be corrected to an ambient temperature of 25 °C. The actual test temperatures shall be used in the separation of losses in the no-load test and in determining the stray-load loss by the direct method.IEEE 112 pdf download.IEEE 112-2017 pdf download

IEEE 112-2017 pdf download

Leave a Reply