IEEE 837-2002 pdf download.IEEE Standard for Qualifying Permanent Connections Used in Substation Grounding

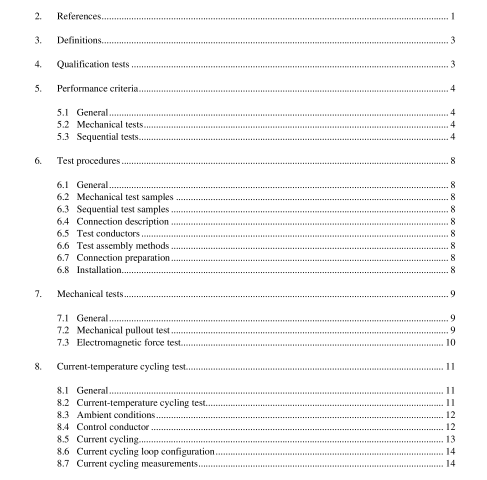

6. Test procedures

6.1 General Mechanical tests are to be conducted on new connections for pullout strength and electromagnetic withstand strength of the connection in accordance with Clause 7.

6.2 Mechanical test samples

The samples subjected to mechanical tests shall not be used for the sequential tests.

6.3 Sequential test samples Current-temperature cycling, freeze-thaw, corrosion, and fault-current tests are to be conducted sequentially.

Use the same samples for all tests conducted in accordance with Clause 8 through Clause 11.

6.4 Connection description A description adequate for complete identification of the test connections shall be included in the test report.

6.5 Test conductors

The conductors shall conform to the following applicable standards: ASTM A363-98, ASTM A510-96, ASTM B1-90, ASTM B2-94, ASTM B3-95, ASTM B8-99, ASTM B49-98, ASTM B105-94, ASTM B172- 95, ASTM B173-95, ASTM B174-95, ASTM B193-95, ASTM B227-98, ASTM B228-98, ASTM B229-95, ASTM B230-97, ASTM B233-97, ASTM B236-95, ASTM B258-96, ASTM B317-96, ASTM B396-87, ASTM B397-85, ASTM B398-97, ASTM B399-97, ASTM B416-98, ASTM B609-97, NEMA GR 1-2001. 6.6 Test assembly methods All assembly details not specifically defined in this standard shall be completely described in the test report.

6.7 Connection preparation

Connections shall be prepared in accordance with the manufacturer’s recommendations for field installation.

6.8 Installation

The method of installation and the installation tooling shall be in accordance with the manufacturers’ recom- mendations for field installation. Unless specified otherwise in the manufacturer’s instructions, the connec- tions shall be installed so as to provide maximum stress on the connector (see Figure 3) during the current- temperature cycling and fault-current tests.

When clamping bolts are employed, they shall be tightened to the torque specified in Table 3, unless other- wise specified by the manufacturer.

7. Mechanical tests

7.1 General

These tests are intended to ensure the reliability of grounding systems against mechanical abuse and electro- magnetic forces. Conductor combination. For a multirange connection, mechanical pullout and electromagnetic force tests shall be performed on the connection joining the largest-to-largest and smallest-to-smallest conductors for which the connection is designed. The conductors used shall be a commercially available hard-drawn type.

NOTE—The selection of a hard-drawn conductor, rather than soft-drawn conductor, will result in a more stringent test.

7.2 Mechanical pullout test

7.2.1 Pullout test samples A minimum of four samples of each connection and conductor combination is required, as described in 7.1, and shall be subjected to each mechanical pullout test.

7.2.2 Pullout test conditions When placing the sample in the tensile testing machine, care shall be taken to ensure that all strands of the conductor are loaded simultaneously and in line with the connection. The length of free conductor between the gripping device and the connection shall not be less than 254 mm. If gripping of the connection is neces- sary, it shall be in a manner that will not influence the pullout value.

7.2.3 Pullout loading speed The load shall be applied at a crosshead speed not exceeding 21 mm per minute per meter of sample length.

7.3 Electromagnetic force test

7.3.1 Electromagnetic force test samples A minimum of four samples of each connection and conductor combination, as described in 7.1, shall be subjected to each electromagnetic force test.

7.3.2 Electromagnetic force test configuration

The test loop consisting of one through four test samples shall be mounted in the same plane with the bus connections, as shown in Figure 3. Equalizers shall be used according to 8.2.3, and conductor length shall be as specified in 8.2.4. The assembled loop may be mounted on an insulated surface of appropriate size.

The use of loosely fitted restraining devices is recommended. This is for safety considerations and to simulate buried ground conduc- tors or connections to ground rods, or both. Restraining devices, such as U-bolts, used to fasten the loop to the board shall be as located in Figure 3. Use of alternate restraining devices, which also will allow free movement of the conductor, is at the option of the tester.IEEE 837 pdf download.IEEE 837 pdf download

IEEE 837-2002 pdf download

Leave a Reply